background

Large lot plant projects are expected to increase in response to overseas demand and trends toward a decarbonized society.

Since 2015, energy plant projects have been stagnant as an overall industry trend due to global financial instability and falling oil prices. Yet orders received have remained largely unchanged (*1). The reason for this is that overseas demand is still high for chemical plants using cheap U.S. gas as feedstock and for energy plants in developing countries as their economies improve. As a result, overseas markets are inevitably more important than domestic markets, which are mostly dominated by aging plants built during the high economic growth period.

In some cases, the value of orders received per project reaches several hundred billion yen, and acquisition of new largescale projects will determine the there financial. Competition for orders is fierce as overseas competitors are growing in terms of price competitiveness. Japanese firms will be required to maintain and improve the high quality and safety standards they have cultivated over the years.

In addition, with the accelerating trend toward a decarbonized society in the wake of global warming, plant construction using renewable energy will also find new avenues of activity.

issue

It was necessary to resolve the operational inefficiencies and uncertain cost structure caused by legacy systems, and to prepare for acquiring large orders.

The following issues needed to be resolved as soon as possible to eliminate the negative aspects of the existing business.

- 1. Poor operational efficiency and lack of productivity

The company was trying to keep the current quality and safety of a legacy system that had been in operation for several decades, and the work had become gentrified. In addition, there was not enough business visualization to enable unskilled members to operate the system, which resulted in poor efficiency and productivity. - 2. Difficult to visualize the cost structure

Risks up to completion of the plant include the client’s business condition, technical/question quality issues, management of suppliers and subcontractors, and exchange rate fluctuations. All of them affect costs. It was difficult to standardize and visualize their structure.

activity

To ensure smooth implementation, we help users and vendors, as well as other concerned members with different backgrounds and experiences, to achieve the same goal.

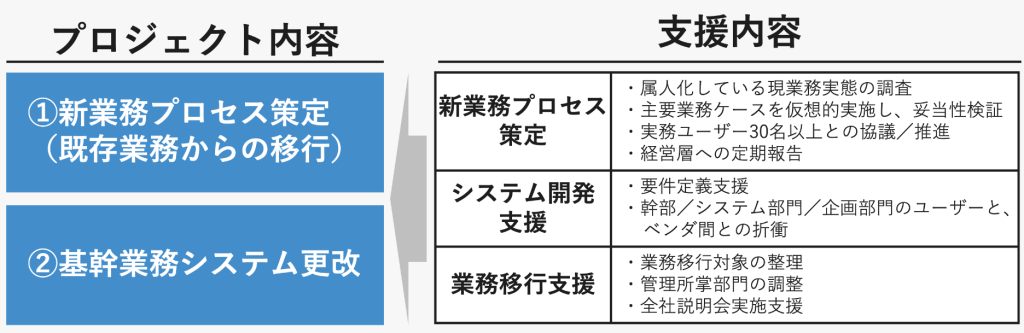

We assisted in the formulation of new business processes, system development and business transition. Specifically, following three points were made.

- 1. We developed measures based on the identification of issues in current business operations. We verified the validity of major business cases and led to discussions and agreement with practical users. In addition, we supported the improvement of overall company operations by providing regular reports to management.

- 2. Provided negotiation support between users and vendors in development from the requirement definition phase to system release.

- 3. Assisted field users and vendors with smooth transition of new business processes and mission critical business systems.

consequence

The new business process, which eliminated personnel handling, has improved operational efficiency. Able to respond to orders for projects with many different characteristics, which contributed to the expansion of the business.

業務習熟メンバの知見・経験を、企業としての業務プロセスや基幹システムに組み込み標準化することにより、案件ごとに異なる特性の様々な国々の海外市場案件業務を効率的にこなせるようになった。 また、新たな基幹業務システムでデータ蓄積を行い、そのデータを使っての将来に向けた品質向上施策を検討・立案し、更なる案件受注、ひいては、事業拡大に貢献した。