background

A manufacturing company began an efficiency improvement project to achieve carbon neutrality.

The issue of climate change (*1) is an unavoidable challenge for each of us and all living things. Climate change is affecting nature and human society and continued emissions of greenhouse gases will increase the risk of serious and widespread impacts on people and ecosystems. In order to stop global warming, the government has declared the goal of carbon neutrality, which means zero emissions of greenhouse gases by the year 2050.

To contribute this goal, major manufacturers in the air conditioning, chemical and filter industries have launched projects to achieve carbon neutrality. The company decided to contribute to carbon neutrality from the following perspectives.

- 1.Reduce waste in their operations and reduce greenhouse gas emissions

- 2.Contribute to the reduction of greenhouse gas emissions by providing a stable supply of environmentally friendly air conditioning, scientific and filter products.

Then, we analyzed operations in order to contribute to carbon neutrality.

issue

An SCP system needs to be implemented to eliminate the increase in work hours and unstable supply of goods caused by inefficient supply chain management.

As a result of the analysis, it was found that there was a major problem in the supply chain. Currently, the supply chain was forced to manually coordinate information divided among production, sales and logistics divisions, thereby increasing the number of work hours due to inefficiencies. In addition, a shortage of workers made the supply of goods unstable. Therefore, it was urgent to reform the supply chain management.

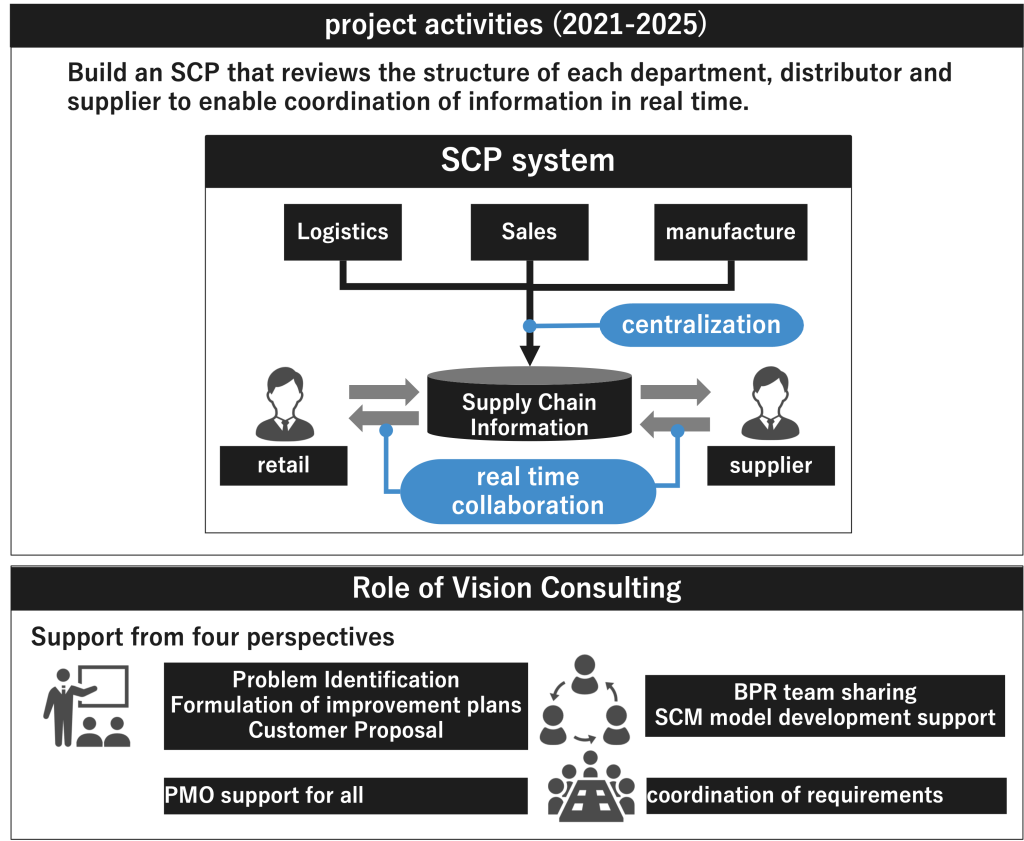

Therefore, a supply chain planning system (SCP system) was implemented to manage all information collectively and visualize mutual influences in order to reform the supply chain management.

activity

As a PMO, supported the introduction of an SCP system that centrally manages all supply chain information and visualizes mutual influences as part of supporting the overall management.

Provided the following support as part of overall management support for implementation of SCP system in a major manufacturing company.

- 1.Identification of issues, formulation of improvement plans and suggestions

- 2.PMO support for the entire project

- 3.BPR Team sharing/support for SCM model development

- 4.Coordination of requirements review with related departments

consequence

Contribute to carbon neutrality by using SCP to improve operational efficiency, reduce greenhouse gas emissions to provide a stable supply of ecofriendly products.

Introduction of SCP system, which centrally manages all supply chain information and visualizes mutual influences, enables centralization and real time coordination of the vast amount of information that occurs daily. As a result, business efficiency will be improved, waste will be eliminated and instability in product supply due to labor shortages will be resolved. Once these problems are solved, we can expect reductions of wasteful greenhouse gases and greenhouse gas emissions due to the stable supply of environmentally friendly products. As a result, activities to become carbon neutral will be promoted and contribute to the elimination of global warming.