Summary

Based on my experience in realizing DX in manufacturing, I will discuss “Expectations for the acceleration of DX through the spread of 5G communication technology” and “The future of technology in the fourth industrial sector" .

1. Introduction

According to the “DX Promotion Index” (*1) by the Ministry of Economy, Trade and Industry, Digital Transformation (DX) is defined as “the transformation of products, services, and business models based on customer and social demands, as well as the transformation of organizations, processes, and corporate culture/climate to establish a competitive advantage, by utilizing data and digital technology in response to rapid changes in the business environment.

This paper describes the author’s experience in DX realization, expectations for DX acceleration with the spread of information and communication technology 5G, and the future of technology.

2. Author’s experience in DX

The author spent about two years in the IT department of a major Japanese manufacturing company to achieve DX of the product lifecycle (R&D, design and development, procurement, production, sales, and maintenance Service).

– The purpose was to change the business model as described below. Transformation from a business that sells products to customers to a business that continues to provide added value even after the products are sold.

– Transform into a business that incorporates customer opinions in the upstream process by feeding them back to the design and other upstream processes at a high speed.

In order to respond to these reforms, the company reformed its business model for customers by utilizing digital technologies such as IoT, ICT, and AI, standardized procurement and sales, and restructured legacy systems.In addition, the Company also sought to develop digital human resources to enable business divisions to speedily develop their own services using digital technology.

2.1 DX overall concept development (*2)

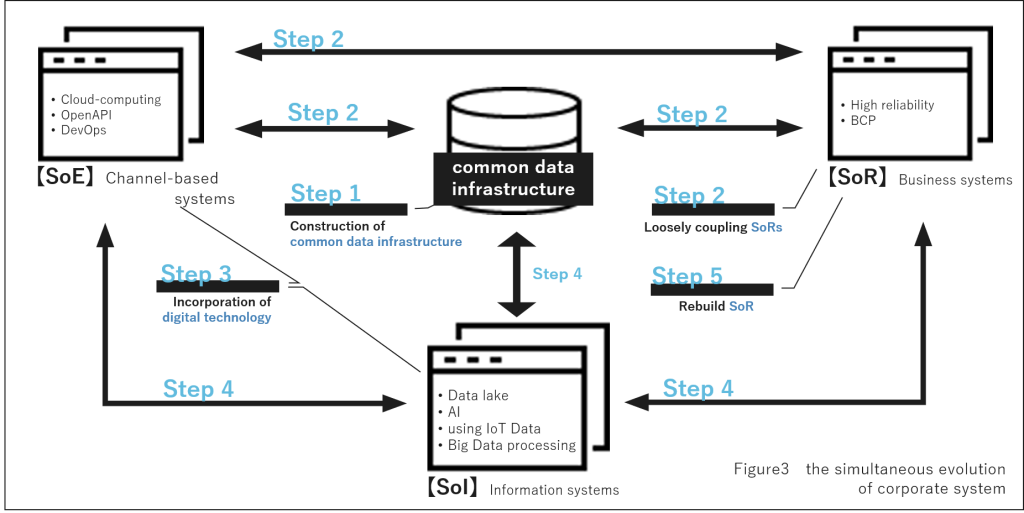

First, a system was established among the parties concerned (management, business divisions, and IT division) to create a common understanding of DX implementation. Next, the parties concerned analyzed the current status of the business and IT systems and conducted a GAP analysis. Then, the entire IT systems subject to DX were classified into the areas of SoE, SoR, SoI Systems of Engagement, Systems of Record, and Systems of Insight according to their roles, and a scenario for simultaneous evolution was created. DX Portfolio management was also conducted.

(1)Outline of SoE, SoR, and SoI

SoE: Channel-based systems that aim to strengthen relationships with customers, making full use of cloud computing, etc. It emphasizes speed and versatility.

SoR: Business systems for the purpose of conducting business within a company, and in many cases, they are legacy systems.

SoI: A group of information systems that aim to understand customer insight (customer needs, etc.) and make full use of AI, etc.

(2)The author created a scenario for the simultaneous evolution of SoE, SoR, and SoI in the following steps.

Step 1: Construction of common data infrastructure (construction of integrated DB environment)

Step 2: Construction of an environment for cooperation with the common data infrastructure, and loosely coupling SoRs

Step 3: Incorporation of digital technology into SoE and SoI

Step 4: Establish an environment to link SoI with SoE and SoR

Step 5: Rebuild SoR (to cope with aging)

2.2 Business model reform

(1)Additional opportunities for contact with customers. The company has realized additional opportunities for contact with customers by distributing operation reports once a month using IoT Data AI, etc. and proposing improvements in product operation, etc., instead of the conventional visits to customers during periodic inspections every few months, etc.

In addition, quality improvement was achieved through feedback of customers’ operational opinions to design, etc.

(2)Preventive maintenance. Preventive maintenance was realized by changing from conventional time-based maintenance (TBM) based on periodic inspections to condition-based maintenance (CBM) based on product operation information.

(3)Systemization of inventory management and automation of procurement. Inventory management systemization, electronic workflow, and automation of parts procurement were realized by replacing manual, paper, and fax-based inventory management, approval, and procurement.

2.3 Micro Service Architecture Implementation and Digital Human Resource Development

Micro Service Architecture was selected and introduced mainly for SoE and SoI, where speed and diversity are important. We also transferred technical capabilities to business divisions and developed digital human resources.

3.Expectations for the DX era with the spread of 5G technology

Currently, 4G is the main communication technology, but the transition to the latest generation 5G, which is scheduled to start commercialization in March 2020, is progressing gradually. 5G is characterized by “high speed and high capacity,” “ultra-low latency,” and “multiple simultaneous connections. The features of 5G will reduce the unit cost of communication and lower the price of data communication. This will make it possible to collect data that cannot be sensed in the past. This will increase demand for IoT such as sensing devices, and IoT prices are expected to decline due to the mass production effect of mass production.

As a result, the spread of 5G is expected to give DX a cost advantage over the current situation and greatly accelerate the process.

4.The Future of Technology in the DX Era (4th Industrial Sector)

The author will discuss the future of technology in the case of the manufacturing industry, which is one of the quaternary industry sectors that the author has dealt with.

According to the Ministry of Economy, Trade and Industry’s “2020 White Paper on Manufacturing” (*3), when asked about management issues facing the manufacturing industry, approximately 42% of both large and small companies cited a “labor shortage,” while 17.1% of large companies and 22.7% of small companies answered a “lack of successors. Therefore, the challenge for the future is to narrow down the tasks that are handled by humans and promote automation in other areas. Even today, DX-enabled companies have examples such as “automation of product appearance inspection using AI image recognition technology and Robot technology” (*4).

In the short term, by taking advantage of the high-speed and ultra-low latency wireless communication features of 5G, it is expected that DX-enabling companies will shift their automation technologies to Cloud computing. As a result, many manufacturers, regardless of company size, will be able to use automation technologies through Cloud computing services. In addition, by utilizing digital technologies such as Wearable Computer and XR, skilled engineers will be able to sense and understand what is happening at manufacturing sites remotely. As a result, one skilled engineer can give work instructions to multiple young engineers by remote control.

The realization of these DXs will enable the transfer of technology, quality maintenance and improvement, and work efficiency improvement, while alleviating labor shortages.

In the mid- to long-term (2030 and beyond), according to “Dr. Ray Kurzweil’s Timeline of the Future” (*5), Avatar Robots are expected to spreads and robots will be commonplace in all places. At manufacturing sites, robots are expected to operate 24 hours a day, 365 days a year in environments where it is difficult for humans to work, such as high/low temperatures and dangerous places at high altitudes, by linking with next-generation communication technologies (e.g., 6G).